Dry Riser

Dry Riser

Enquiry

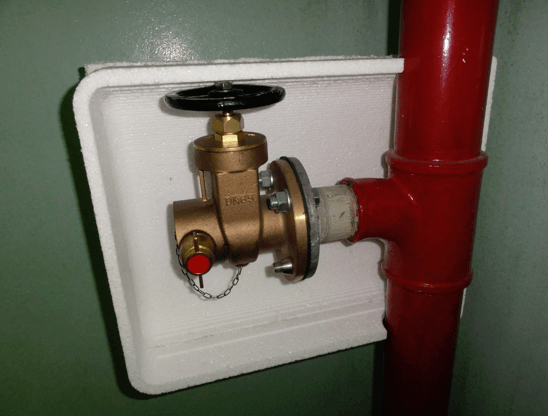

Portsmouth City Council were looking for a local company to design and produce GRP Dry Riser Covers for two blocks of flats they were responsible for. Vandalism to the flats Dry Riser Valves hindered the fire services tackling a recent fire, which resulted in costly refurbishment to some of the flats.

Design Brief

To produce a robust cover which encompassed and protects the valve and fire hose outlet from vandalism which was lockable with a padlock, but also easily removed once unlocked by the fire services.

Process

A site survey was carried out to take measurements and determine the best solution for the design brief.

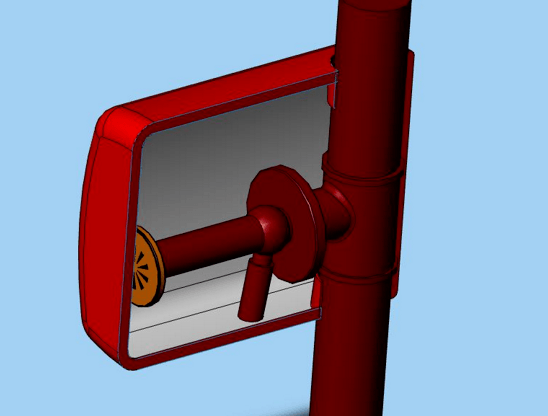

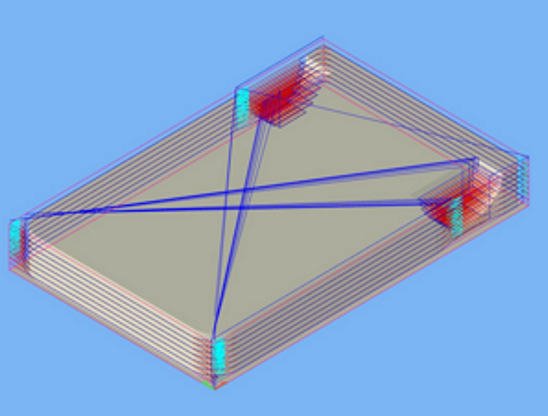

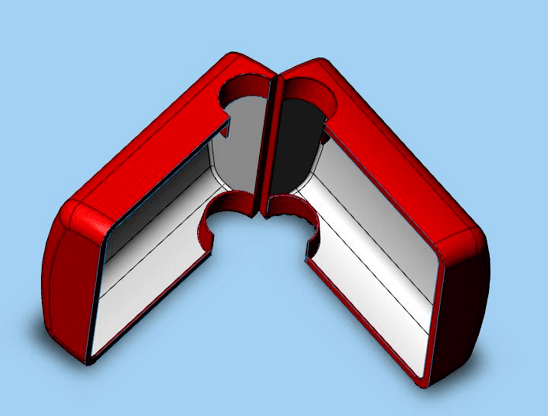

A 3D model of the Dry Riser was drawn up in CAD and a basic cover designed around this. This was sent to the customer for approval. Once approved the final design was drafted in 3D CAD hinged and analysed to ensure the cover was removable within the constraints of the Dry Risers location.

Two mouldings were produced to make the cover set and fitted out with lift off hinges and a pad lockable latch, these were then delivered and assembled at site.

"Unable to find a suitable product for this application, I approached Henleycraft to produce a bespoke solution. From initial consultation, to design and final fitting of the Dry Riser covers, they were excellent and this project has helped us meet legislative challenges whilst combatting vandalism."

Ian Slade - Property and Construction (Health and Safety) Manager

Portsmouth City Council

All Rights Reserved | Henleycraft Ltd

© 2024